The manufacturing industry is undergoing a dramatic transformation driven by Industry 4.0 principles, characterized by increased automation, data integration, and real-time control. At the heart of this revolution are Computer Numerical Control (CNC) machine tools, which are becoming increasingly sophisticated and demanding. A crucial component of modern CNC systems is the DC gear motor, responsible for providing precise and powerful motion control. New-generation DC gear motors are evolving rapidly, presenting innovative solutions for enhanced performance, efficiency, and flexibility within CNC applications. This article will explore the key application trends shaping the selection of these motors, focusing on advancements like direct-drive technology, intelligent control systems, and the integration of AI for predictive maintenance – especially crucial amidst concerns around supply chain disruptions and rising energy costs.

Traditional CNC machine tools relied heavily on AC servo motors. However, DC gear motors are gaining significant traction due to their inherent advantages in certain applications. These advantages include higher torque at lower speeds, simplified control, and generally lower cost, particularly for applications that don't require the extremely high speeds of AC servo motors. The demand for higher precision, faster cycle times, and increased adaptability is driving the evolution of DC gear motor technology. Specifically, advancements in materials science, power electronics, and control algorithms are contributing to a new generation of motors capable of meeting these stringent requirements. The rise of additive manufacturing (3D printing) and complex geometries further necessitates precise and responsive motion control, fueling the need for more advanced DC gear motor solutions.

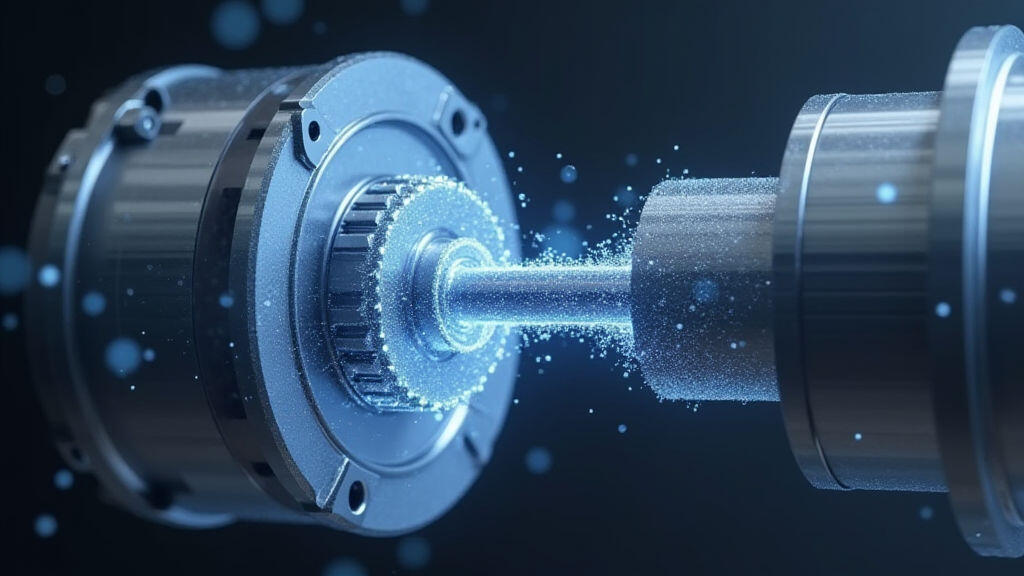

One of the most significant trends is the increasing adoption of direct-drive DC gear motors. Traditionally, CNC systems have utilized a multi-stage gearbox to reduce motor speed and increase torque. Direct-drive systems eliminate this intermediary gearbox, connecting the motor directly to the spindle or other critical components. This offers several compelling benefits:

The implementation of direct-drive DC gear motors is particularly beneficial in applications such as milling, turning, and grinding, where high precision and rapid movements are essential. MES-Drive offers a range of direct-drive solutions optimized for these demanding tasks.

Modern DC gear motors are increasingly equipped with sophisticated intelligent control systems. These systems leverage advanced algorithms to optimize motor performance in real-time, adapting to varying loads and operating conditions. Key features of these intelligent systems include:

These advanced control systems enable CNC machines to operate with greater efficiency, accuracy, and responsiveness.

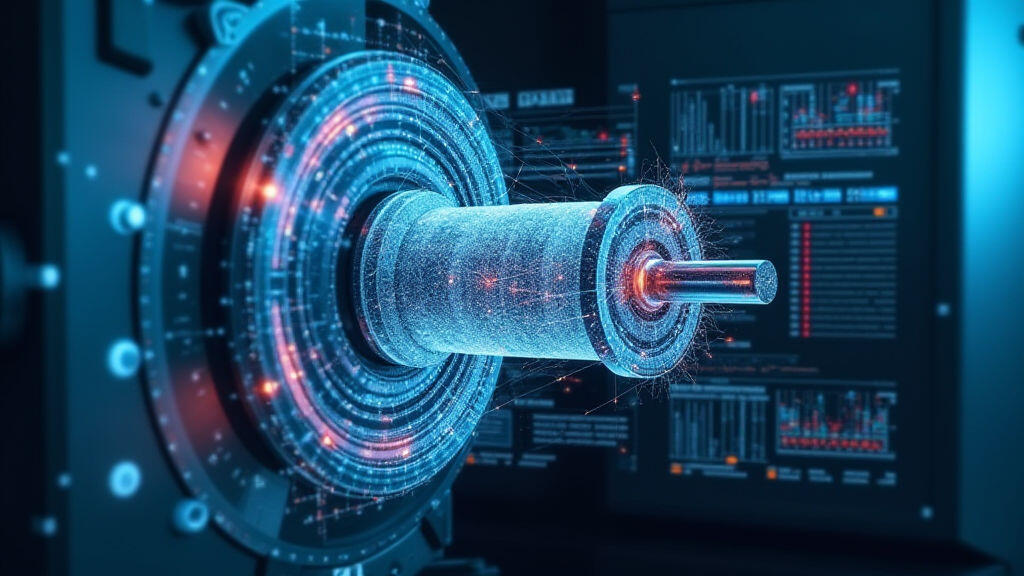

The rising cost of downtime is a major concern for CNC machine tool operators. AI-powered predictive maintenance is emerging as a critical solution for minimizing disruptions and maximizing machine uptime. New-generation DC gear motors are being integrated with sensors and data analytics platforms to enable proactive maintenance.

MES-Drive is actively researching and implementing AI-powered predictive maintenance solutions for its DC gear motors, providing customers with valuable insights into motor health and helping them optimize maintenance schedules. This is particularly timely given current global supply chain constraints which often lead to delays in procuring replacement parts.

Another noteworthy trend is the miniaturization of DC gear motors. Advancements in motor design and manufacturing processes are enabling the creation of smaller, lighter motors without sacrificing performance. This trend is driven by the increasing demand for compact CNC machines and the need to integrate motor systems seamlessly into complex machine tool architectures. Further, incorporating integrated functionalities such as position feedback and communication interfaces (e.g., Ethernet/CAN bus) within the motor itself streamlines system integration.

The selection of DC gear motors for CNC machine tools is undergoing a significant transformation. Direct-drive technology, intelligent control systems, AI-powered predictive maintenance, and miniaturization are key trends that are driving innovation and enhancing the performance of modern CNC systems. As Industry 4.0 principles continue to permeate the manufacturing sector, the demand for these advanced DC gear motor solutions will only increase. MES-Drive remains committed to leading this innovation, providing customers with high-performance, reliable, and intelligent motor solutions that address the evolving challenges of CNC manufacturing. The current economic climate, characterized by volatility and supply chain uncertainties, further underscores the importance of proactive maintenance and optimized system performance – areas where AI-driven solutions are poised to play a transformative role. Investing in these next-generation DC gear motors is not just about improving machine performance; it's about securing a competitive edge in the future of manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked